eco-design

a durable design

Renault Scenic

Renault Scenic E-Tech electric embodies Groupe Renault’s commitment to sustainable development. As a forerunner in this field, the vehicle uses optimised processes and and includes at least 18% recycled materials¹ and 24% materials from the circular economy⁽²⁾ ⁽³⁾. At the end of its life, 90%⁴ of its mass – including the battery – can be recycled through industrial recycling channels. Built in France, it opens the way for a more responsible and safer mobility.

The battery, which is mostly recyclable at 65%⁸ is made up of 12 modules that can be easily exchanged individually in over 20 battery repair centers in Europe . At the end of the vehicle’s life, if it is in good enough condition, it can be reused to store energy for various purposes.

recycled comfort

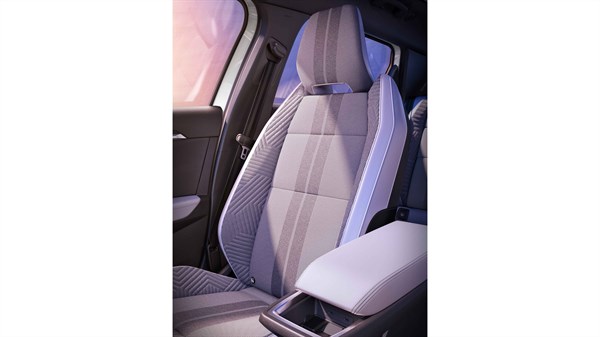

No leather is used in the passenger compartment of Scenic E-Tech electric – it is replaced by recycled materials. These materials have a lower carbon footprint than leather, without compromising on the visual quality, feel and comfort.

seats: 87% recycled fibres for fabrics in the iconic version

dashboard structure – up to 80% recycled materials

solarbay® opacifying panoramic glass roof: glass made from at least 50% recycled materials

an overriding ambition

promoting the circular economy

Designing vehicles according to the philosophy of the circular economy is an overriding ambition for Renault Group. The Group intends to be at the forefront of the circular economy by using fabrics, plastics, glass and metals that include recycled materials, refurbishing spare parts or reusing batteries, and by 2030 we aim to reach 33% of recycled materials from recycling our own vehicles.

¹ according to the ISO 14021 standard.

² including materials recycled in compliance with the ISO 14021 standard and production offcuts or scraps reincorporated into manufacturing processes at an industrial site.

³ based on 87 kWh battery, estimate currently being consolidated.

⁴ majority recyclable product, recyclability rate rounded up to 90%, actual value greater than 89.72% of its mass in accordance with European Directive 2005/64/EC on the type-approval of motor vehicles with regard to their re-usability, recyclability and recoverability.

⁵ i.e. 17% of the total mass of thermoplastics and polyurethane foams present in the vehicle (239 kg).

⁶ depending on version

⁷ available on techno and Alpine spirit versions representing more than 50% of 2024 sales forecasts.

⁸ majority recyclable product, based on industrial recycling processes available in Europe by 2025: